Issue 9 - Biodegradation testing

Although there is strong science on the breakdown of PBS in nature, we are not working with a pure PBS and every additional copolymer or additive will have some effect on the rate and method of degradation. While we know that BiodolomerOcean can and will biodegrade, questions regarding its useful lifespan and rate of degradation are still to be answered precisely.

Four different grades are currently being tested for degradation and loss of tensile properties by SINTEF in Norway, using a variety of analytical tools.

Preliminary sampling of BiodolomerOcean after 6 months in marine sediment shows the material has not started the accelerated biodegradation process and that it remains intact both visibly, chemically, and mechanically.

These findings are good for the project as they imply that the material does not suffer a quick breakdown of the mechanical properties and that the material stands a chance to continue to perform in marine environments within the work-life needed by the industry.

The biodegradation testing at SINTEF will continue for another 24 months to monitor if microbes have started to assemble on the surface of the filament and have begun to compromise the material properties.

Plans are also in place to extend the laboratory tests to biodegradation testing after at-sea deployment of the material. This will provide us with direct proof of microbial bond breaking or de-polymerization in natural marine systems.

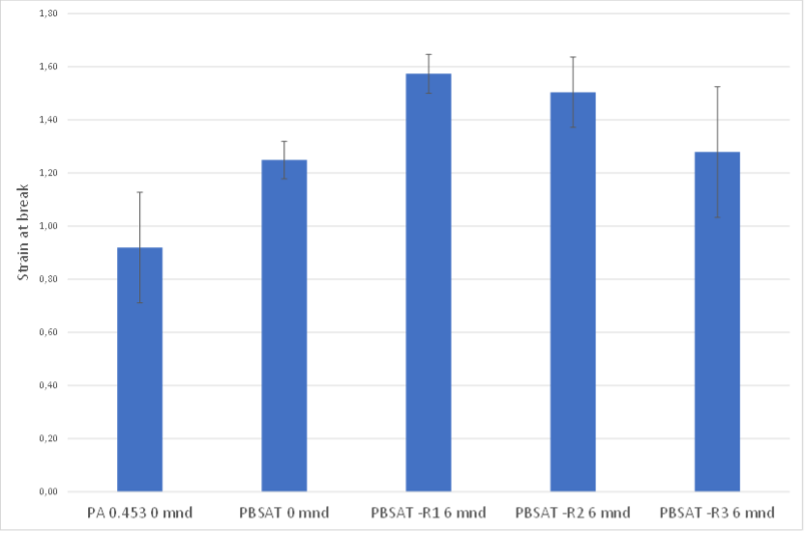

FTIR testing shows that there has been some loss of surface material and a small reduction in tensile strength. This primary degradation is likely a result of the removal of lower molecular species from the surface as predicted, potentially due to hydrolysis. This is indicated by a shift in the carbonyl peaks from 1715cm-1 to 1711cm-1 in some of our grades. The surface roughness has also increased slightly in at least two of the samples. This may be indicative of biodegradation, in line with previous research that has demonstrated slow biodegradation of a PBS-PBAT blend in cold seawater.

SEM analysis of the samples shows that the roughness of the surface area of the samples has not increased after 6 months. This also tells us that the material remains intact.

The result after tensile testing indicate that the mechanical properties of the samples remain the same and that the material does not suffer a quick breakdown of the machanical properties.